|

|

|

|

|

파이프 자동용접기

고정된 파이프의 원주(Orbit)를 따라 가이드링을 설치해 놓고 용접토치가 그 위를 주행하면서 자동용접되도록 한 장치를 말하는데, 이러한 용접법을 "오비털용접(Orbital Welding)" 또는

"파이프자동용접"이라고 부릅니다. 이 용접법은 파이프 뿐 아니라 탱크나 벳셀 등의 자동용접에도 활용되고 있습니다.

제살용접 제살용접

|

Magnatech 제품

|

C-2.5, C-5, C-5, C-10,

C-25, C-35, C-45

|

|

Prai 제품

|

M41, M42

|

|

|

|

Model

|

M41

|

M42

|

|

Range

|

External Diameter 25 - 115 mm

|

External Diameter 6 - 38 mm

|

|

Welding Procedure

|

TIG

|

TIG

|

|

Welding Position

|

Horizontal, Vertical, Inclined

|

Horizontal, Vertical, Inclined

|

|

Welding Current

|

Max 120 A

|

Max 100 A

|

|

Main Body

|

Water Cooled

|

Water Cooled

|

|

Ground

|

Contact on Clamps

|

Contact on Clamps

|

|

Rotation motor

|

18 VDC Motor with Tacho

Feedback

|

18 VDC Motor with Tacho

Feedback

|

|

Rotation Speed

|

Min

0,3 rpm

|

Min

0,5 rpm

|

|

Max 2,0 rpm

|

Max 6,0 rpm

|

|

Electrode

Diameter

|

1,6

- 2,4 mm

|

1,6

- 2,4 mm

|

|

(Standard 2,4

mm)

|

(Standard 2,0 mm)

|

|

Weight

|

4

Kg

|

3

Kg

|

|

(without Cable)

|

(without Cable)

|

|

Option

|

Water Cooled Clamps

|

Water Cooled Clamps

|

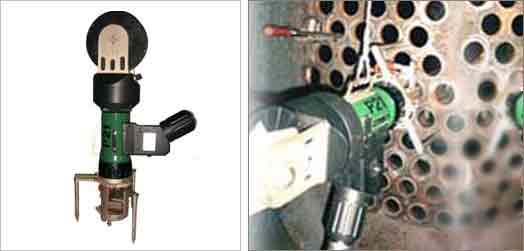

| < M41> |

|

| < M42> |

|

3T이하 용접 3T이하 용접

|

Magnatech제품

|

R-1, R-2, R-3, E-Head

|

|

Prai제품

|

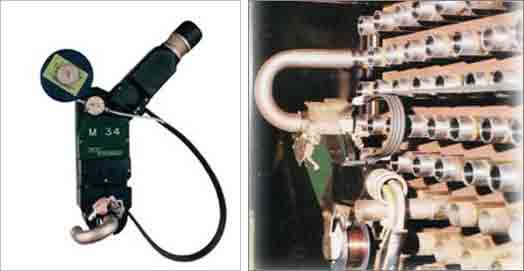

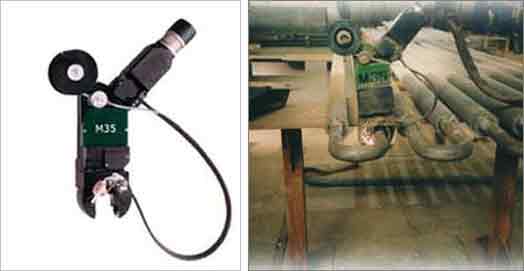

M33, M34, M35, M36, M39

|

| < E-HEAD> |

|

|

Model

|

M33

|

M34

|

M35

|

M36

|

M39

|

|

Torch Position Control

|

Pulse Emitter

|

Pulse Emitter

|

Pulse Emitter

|

Pulse Emitter

|

Pulse Emitter

|

|

Range

|

External Diameter 12- 46 mm

|

External Diameter 12 - 46 mm

|

External Diameter 12 - 51 mm

|

External Diameter 50 - 102 mm

|

|

|

Welding Procedure

|

TIG and TIG + Filler Wire

|

TIG and TIG + Filler Wire

|

TIG and TIG + Filler Wire

|

TIG and TIG + Filler Wire

|

TIG and TIG + Filler Wire

(optional)

|

|

Welding Position

|

Horizontal, Vertical, Inclined

|

Horizontal, Vertical, Inclined

|

Horizontal, Vertical, Inclined

|

Horizontal, Vertical, Inclined

|

Horizontal, Vertical, Inclined

|

|

Welding Current

|

Max 200 A

|

Max 200 A

|

Max 200 A

|

Max 200 A

|

Max 200 A

|

|

Horseshoe Clamp

|

Water Cooled

|

Water cooled

|

Water Cooled

|

Water Cooled

|

|

|

Machine Body

|

Water Cooled

|

Water cooled

|

Water Cooled

|

Water Cooled

|

|

|

Torch

|

Water Cooled

|

Water cooled

|

Water Cooled

|

Water Cooled

|

Water Cooled

|

|

Supply of Gas,

Water and Current to Torch

|

Self Wrapping Viton Hose

|

Self Wrapping Viton Hose

|

Self Wrapping Viton Hose

|

Self Wrapping Viton Hose

|

By multiple Viton Hose to Torch

|

|

Rotation / Wire Motor

|

18

VDC Standard with

|

18

VDC Standard Motors or

|

18

VDC Standard Motors or

|

18

VDC Standard Motors or

|

18

VDC or

|

|

Tacho Feedback

|

with Tacho Feedback

|

with Tacho Feedback

|

with Tacho Feedback

|

Tacho (on request)

|

|

Rotation Speed

|

Min

0,3 rpm

|

Min

0,3 rpm

|

Min

0,3 rpm

|

Min

0,3 rpm

|

0,3 - 2,0 rpm

|

|

Max 2,0 rpm

|

Max 2,0 rpm

|

Max 2,0 rpm

|

Max 2,0 rpm

|

|

|

Wire Speed

|

Min

0,15 m/min

|

Min

0,15 m/min

|

Min

0,15 m/min

|

Min

0,15 m/min

|

0,15 - 1,60 m/min

|

|

Max 1,60 m/min

|

Max 1,60 m/min

|

Max 1,60 m/min

|

Max 1,60 m/min

|

|

|

Filler Wire Feeding

Unit

|

Mounted

on Machine Body

|

Mounted

on Machine Body

|

Mounted

on Machine Body

|

Mounted

on Machine Body

|

Mounted separately on Machine

Body

|

|

(1 Kg Spool)

|

(1 Kg Spool)

|

(1 Kg Spool)

|

(1 Kg Spool)

|

|

|

Electrode Diameter

|

1,6

- 2,4 mm

|

1,6

- 2,4 mm

|

1,6

- 2,4 mm

|

1,6

- 2,4 mm

|

1,6

- 2,4 mm

|

|

(Standard 2,4

mm)

|

(Standard 2,4 mm)

|

(Standard 2,4)

|

(Standard 2,4 mm)

|

(Standard 2,4 mm)

|

|

Filler Wire Diameter

|

0,6 - 0,8 mm

|

0,6 - 0,8 mm

|

0,6 - 0,8 mm

|

0,6 - 0,8 mm

|

|

|

Overall Dimension on

Tube

|

Total

80 mm,

|

Total

135 mm,

|

Total

135 mm,

|

Total

135 mm,

|

|

|

Clamp to

Electrode 65 mm

|

Clamp to Electrode 120 mm

|

Clamp to Electrode 120 mm

|

Clamp to Electrode 120 mm

|

|

|

Weight

|

5,5

Kg

|

5,5

Kg

|

6

Kg

|

7

Kg

|

7

Kg

|

|

(without

Connecting Cable)

|

(without Connecting Cable)

|

(without Connection Cable)

|

(without

Connection Cable)

|

(without Wire Unit)

|

| < M33 > |

|

| < M34> |

|

| < M35 > |

|

| < M36 > |

|

| < M39 > |

|

3T 이상 용접 3T 이상 용접

| Magnatech제품

|

D-Head, T-Head, Quickclamp(432, 433)

|

| Prai제품

|

M35M, M36M

|

| < D-HEAD> |

|

|

|

|

MODEL

|

M35M

|

M36M

|

|

Torch Position Control

|

Pulse Emitter

|

Pulse Emitter

|

|

Range

|

External Diameter 31,8 - 51 mm

|

External Diameter 51 - 102 mm

|

|

Welding Procedure

|

TIG + Filler Wire

|

TIG + Filler Wire

|

|

Welding Position

|

Horizontal, Vertical, Inclined

|

Horizontal, Vertical, Inclined

|

|

Welding Current

|

Max 200 A

|

Max 200 A

|

|

Horseshoe Clamp

|

Water Cooled

|

Water Cooled

|

|

Machine Body

|

Water Cooled

|

Water Cooled

|

|

Torch

|

Water Cooled

|

Water Cooled

|

|

Supply of

Gas, Water and Current to Torch

|

Self Wrapping Viton Hose

|

Self Wrapping Viton Hose

|

|

Rotation / Wire Motor

|

18

VDC Standard Motors or

|

18

VDC Standard Motors or

|

|

with Tacho

Feedback

|

with Tacho Feedback

|

|

Rotation Speed

|

Min

0,3 rpm

|

Min

0,3 rpm

|

|

Max 2,0 rpm

|

Max 2,0 rpm

|

|

Wire Speed

|

Min

0,15 m/min

|

Min

0,15 m/min

|

|

Max 1,60 m/min

|

Max 1,60 m/min

|

|

Filler Wire Feeding

Unit

|

Mounted

on Machine Body

|

Mounted

on Machine Body

|

|

(1 Kg Spool)

|

(1 Kg Spool)

|

|

Electrode Diameter

|

1,6

- 2,4 mm

|

1,6

- 2,4 mm

|

|

(Standard 2,4

mm)

|

(Standard 2,4 mm)

|

|

Filler Wire Diameter

|

0,6 - 0,8 mm

|

0,6 - 0,8 mm

|

|

Overall Dimension on

Tube

|

Total

170 mm,

|

Total

170 mm,

|

|

Clamp to

Electrode 140 mm

|

Clamp to Electrode 140 mm

|

|

AVC Stroke

|

16 mm

|

22 mm

|

|

Oscillation Stroke

|

12 mm

|

16 mm

|

|

Weight

|

7

Kg

|

8

Kg

|

|

(without

Connecting Cable)

|

(without Connection Cable)

|

| < M35M > |

|

| < M36M > |

|

TUBESHEET 용접 TUBESHEET 용접

|

|

| Magnatech 제품 |

Tubesheet(450, 550, 750)

|

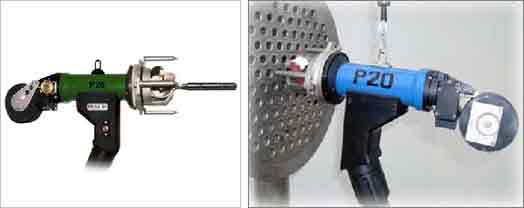

| Prai 제품 |

P16, P16M, P20, P21

|

|

|

| MODEL |

P16 |

P16M |

P20 |

P21 |

| Welding Position |

Horizontal, Vertical |

Horizontal, Vertical |

Horizontal, Vertical |

Horizontal (Vertical) |

| Torch Position Control |

Pulse Emitter |

Pulse Emitter |

Pulse Emitter |

Pulse Emitter |

| Wedling Current |

Max 200 A |

Max 200 A |

Max 200 A |

Max 250 A |

| Current Transmission |

Lamellar Coupling |

Lamellar Coupling |

Lamellar Coupling |

Lamellar Coupling |

| Front Ring |

Stainless Steel |

|

|

|

| Mandrel Support Vessel |

Stainless Steel |

Three Point Support or Front

Ring |

Stainless Steel |

Stainless Steel |

| Machine Body Cooling |

Water |

Water |

|

|

| Transmission Water, Gas |

Rotating Coupling |

Rotating Coupling |

Routating Coupling |

Rotating Coupling |

| Weight with Filler Wire

unit |

10 Kg |

11 Kg |

6 Kg |

|

| Weight without Filler

Wire unit |

8 Kg |

9 Kg |

5 Kg |

|

| Rotation / Wire Motor |

18 VDC Standard Motors

or with Tacho Feedback |

18 VDC Standard Motors

or with Tacho Feedback |

18 VDC

Standard Motors,Rotation Motor with Tacho Feedback |

24 / 18 VDC Motors with Tacho

Feedback |

| Rotation Speed |

Min

0,33 rpm |

Min

0,33 rpm |

Min

0,33 rpm |

Min

0,33 rpm |

| Max 6,0 rpm |

Max 6,0 rpm |

Max 6,0 rpm |

Max 6,0 rpm |

| Front Support |

|

|

Three Point Support |

Three Point Support |

| Torch Cooling |

|

|

Water up to Electrode |

Water Cooled |

| Torch |

|

|

|

Adjustable on

three Axis according to Welding Geometry |

| Distance Regulation |

|

|

|

Micrometrical regulation

stroke +/- 5 mm |

| Wire Speed |

|

|

|

Up to 16 m/min |

| Wire Spool |

|

|

|

5

Kg Spool |

| |

|

|

Mounted on Machine Body |

| Wire Unit |

|

|

|

Rotates Coaxially with the

Torch |

| Wire Unit |

|

|

|

Standard 1,0 mm |

| Weight |

|

|

|

12 Kg |

| Welding Procedure |

|

|

|

MIG / MAG |

| Tube Diameters |

|

|

|

50

- 80 mm with Torch Inclined at 30 Degrees |

| |

|

|

80 - 140 mm with Torch

Parallel to the Tube |

| Welding Geometries |

|

|

|

Recessed, Flush and Protruding

Tubes |

| < P16 > |

|

| < P16M > |

|

| < P20 > |

|

| < P21 > |

|

미그용접 미그용접

|

PIPELINER Ⅱ- Weld Head Models 607

& 609

|

|

Application

|

Pipe size- 168mm(6.625") and larger

Pipe Wall Thickness-unlimited

Fix-TrackTM

for welding on flat and curved surfaces

|

|

Oscillation Module(Linear)

Oscillation

Stroke Amplitude

Oscillation

Speed

Oscillation

Dwell

Cross

Seam Adjustment

|

0-5.1cm(2")

0-254cm/min. (100ipm)

0-1 second. Independently adjustable at

either oscillation stroke

endpoints.

±2.5cm(1.00")

|

|

Torch Vertical Motion Module

Stroke

Speed

|

6.6cm(2.625") (motorized)

152cm/min. (60ipm) maximum

|

|

Tractor Module

Speed

Capability

Travel

Direction

|

Poly-Track Propulsion (Patent Pending)

0-76.2 cm/min. (30 ipm). Higher speed

motors available

Switch selectable (on Head)

|

|

Water-Cooled Torch

Amperage

Capability

|

300 Amps Continuous. Uses standard components

|

|

Cable Length

|

Wire Feeder on Head - 15mm (50")

Standard

Wire Feeder on Floor - 4.6mm (15")

Standrad

|

|

Torch Adjustment Capability

Troch

Lead/Lag Adjustment

Torch

Tilt Adjustment

|

±5 Degrees (manual)

±10 Degrees (manual) - Optional

angle bracket ±45

degrees.

|

|

Model

|

Axial

Length

( A )

|

Minimun

Radial

Clearance

( B )

|

Overall

Width

( C )

|

Weitht

|

|

607

WFOF

|

37.5cm

14.75"

|

24.1cm

9.50"

|

34.3cm

13.50"

|

9.8 kg

21.5 lbs.

|

|

607

|

59.7cm

|

27.9cm

|

38.1cm

|

14.4kg

|

|

WFOH

|

23.5"

|

11"

|

15"

|

31.75lbs.

|

|

609

|

38.7cm

|

24.8cm

|

30.5cm

|

9.8kg

|

|

WFOF

|

15.25"

|

9.75"

|

12"

|

21.5 lbs.

|

|

609

|

66.7cm

|

26.7cm

|

36.8cm

|

14.4kg

|

|

WFOH

|

26.25"

|

10.5"

|

14.5"

|

31.75lbs.

|

|

C-HEAD(제살용접) C-HEAD(제살용접)

|

단위 : mm초, (분:초)

|

|

외경 |

두께 |

재질 |

아크타임 |

용접전후

총 Purge Time |

기계착탈 시간 |

포인트당

총용접시간 |

15 |

1.5 |

스텐레스강 |

50 |

20 - 30 |

15 |

1:30 |

25 |

1.5 |

스텐레스강 |

60 |

20 - 30 |

15 |

1:40 |

35 |

1.5 |

스텐레스강 |

80 |

20 - 30 |

15 |

2:00 |

|

|

RED-HEAD(와이어 사용, SQUARE BUTT ONE-PASS용접)

|

파이프

사이즈 |

두께 |

재질 |

아크타임 |

용접전후

총 Purge Time |

기계착탈 시간 |

포인트당

총용접시간 |

40A |

2.8 |

스텐레스강 |

1:30 |

10 - 20 |

60 |

2:45 |

80A |

2.8 |

스텐레스강 |

2:30 |

10 - 20 |

60 |

3:45 |

|

|

D-HEAD(또는 T-HEAD)

|

외경 |

두께 |

재질 |

아크타임 |

용접전후

총 Purge Time |

기계착탈 시간 |

포인트당

총용접시간 |

50A |

3.9 |

탄소강 |

2 |

6:00 |

5:00 |

11:00 |

100A |

6.0 |

탄소강 |

3 |

17:00 |

5:00 |

22:00 |

200A |

8.2 |

탄소강 |

4 |

45:00 |

5:00 |

50:00 |

|

|

PIPELINER(ROOT PASS 수동용접분 제외)

|

파이프사이즈

(인치) |

스케쥴 |

두께 |

총 용착량

(kg) |

포인트당 용접시간(시간:분) |

효율100% |

효율75% |

6 - 5/8 |

40 |

7.1 |

0.36 |

0:07 |

0:12 |

10 - 3/4 |

80 |

1.1 |

1.80 |

0:34 |

0:48 |

14 |

160 |

35.7 |

10.4 |

3:17 |

4:24 |

20 |

40 |

15.1 |

3.33 |

1:03 |

1:24 |

36 |

80 |

12.7 |

4.60 |

1:26 |

2:18 |

|

Head Head

제품소개 제품소개

홈으로 홈으로

|

|

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()